Manchester has a rich history intertwined with woodworking and the machinery that drives it. From traditional craftsmanship to modern industrial production, Manchester woodworking machinery has played a vital role in shaping the industry. This guide delves into the world of Manchester woodworking machinery, exploring its history, types, applications, and future trends.

Exploring the History of Manchester Woodworking Machinery

Manchester’s prominence in the Industrial Revolution significantly influenced the development of woodworking machinery. The city’s textile industry fueled the demand for efficient and precise woodworking tools, leading to innovations like the power loom and steam-powered saws. These advancements laid the foundation for modern woodworking machinery and established Manchester as a hub for its production and distribution.

The early 20th century saw further advancements with the introduction of electric motors and specialized machines for specific woodworking tasks. Manchester’s engineering expertise played a crucial role in designing and manufacturing these machines, catering to both local and international markets.

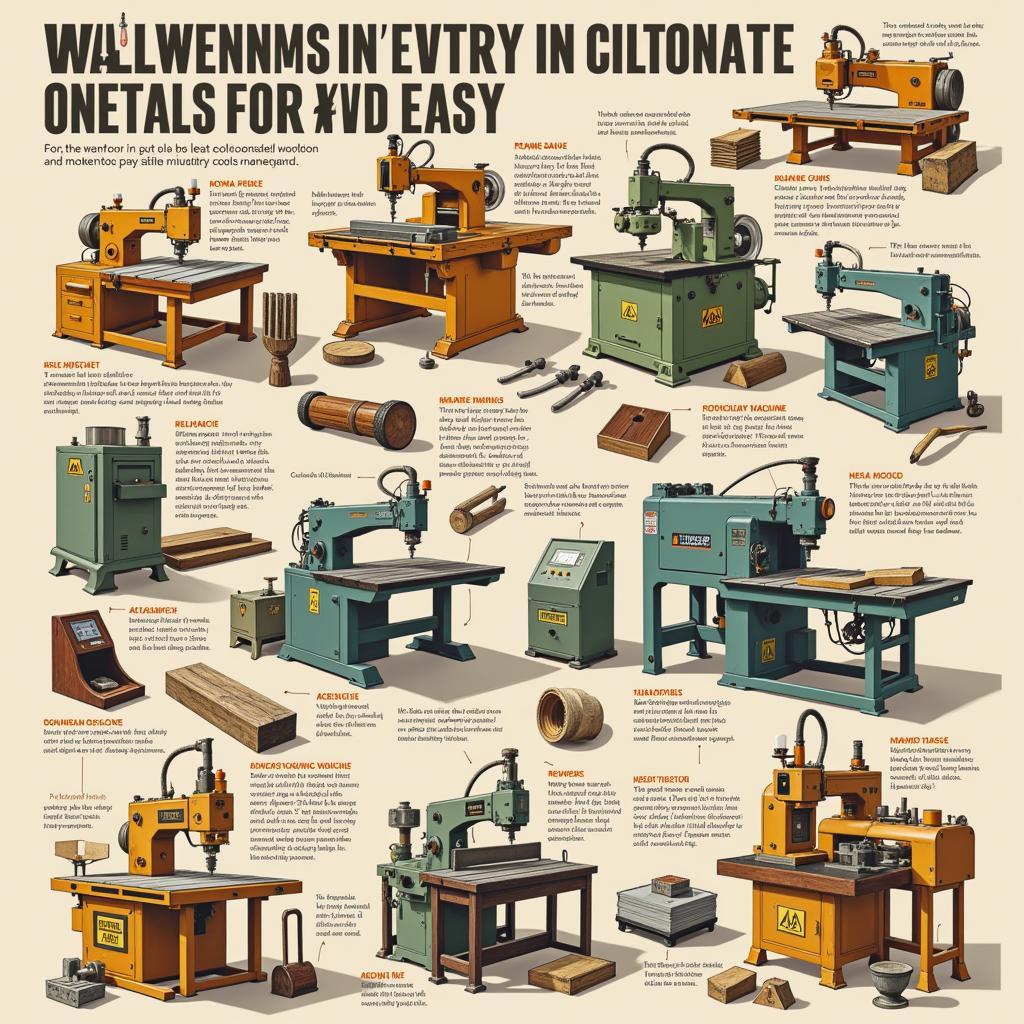

Types of Manchester Woodworking Machinery

Manchester woodworking machinery encompasses a wide range of tools and equipment designed for various woodworking operations. These include:

- Saws: Circular saws, band saws, and table saws for cutting wood to specific dimensions.

- Planers: Surface planers and thickness planers for smoothing and shaping wood surfaces.

- Jointers: For creating flat and straight edges on wood pieces.

- Routers: For shaping decorative edges and profiles.

- Sanders: Belt sanders, orbital sanders, and drum sanders for smoothing wood surfaces.

- CNC Routers: Computer-controlled routers for precise and intricate cutting and carving.

- Lathes: For turning wood into cylindrical shapes.

- Drill Presses: For drilling precise holes in wood.

Applications of Manchester Woodworking Machinery

Manchester woodworking machinery finds applications in various industries and sectors, including:

- Furniture Manufacturing: From traditional to contemporary furniture styles, these machines are essential for producing high-quality furniture pieces.

- Construction: Used in creating structural components, flooring, and other wood-based building materials.

- Cabinet Making: Crafting custom cabinets and storage solutions.

- Musical Instrument Making: Precise and delicate woodworking is crucial in creating musical instruments.

- Art and Sculpture: Woodworking machinery allows artists to create intricate sculptures and artwork.

Future Trends in Manchester Woodworking Machinery

The future of Manchester woodworking machinery is marked by automation, precision, and sustainability. The integration of advanced technologies like artificial intelligence and robotics is expected to further enhance efficiency and productivity. There is also a growing emphasis on sustainable practices, with manufacturers focusing on energy-efficient machines and eco-friendly materials.

Conclusion

Manchester woodworking machinery has a long and rich history, playing a pivotal role in the development of the woodworking industry. From its roots in the Industrial Revolution to the advanced technologies of today, Manchester continues to be a center for innovation and excellence in woodworking machinery. Investing in high-quality Manchester woodworking machinery is crucial for businesses and individuals looking to achieve precision, efficiency, and sustainability in their woodworking endeavors.

FAQ

- What are the key advantages of using Manchester woodworking machinery?

- How do I choose the right woodworking machine for my needs?

- What are the maintenance requirements for woodworking machinery?

- Where can I find reputable suppliers of Manchester woodworking machinery?

- What safety precautions should I take when operating woodworking machinery?

- What are the typical costs associated with Manchester woodworking machinery?

- Are there financing options available for purchasing woodworking machinery?

Mô tả các tình huống thường gặp câu hỏi.

Khách hàng thường hỏi về giá cả, hiệu suất, bảo hành và dịch vụ sau bán hàng của máy chế biến gỗ Manchester. Ngoài ra, họ cũng quan tâm đến tính an toàn, khả năng đào tạo vận hành máy và nguồn cung cấp phụ tùng thay thế.

Gợi ý các câu hỏi khác, bài viết khác có trong web.

Bạn có thể tìm hiểu thêm về các loại máy chế biến gỗ cụ thể như máy cưa, máy bào, máy phay trên website của chúng tôi. Chúng tôi cũng có các bài viết về kỹ thuật vận hành máy, bảo trì máy và các mẹo an toàn khi làm việc với máy chế biến gỗ.